Discovery & Development: Viral Vectors

Five Factors Driving Cell and Gene Therapy Developers Towards Gammaretrovirus

What has led to the rising trend for Cell & Gene Therapy (CGT) developers to choose retroviral vectors over other potential vectors, and what are the many drivers behind this selection process?

Pratima Cherukuri at Genezen

The CGT space is expanding rapidly, offering revolutionary personalised treatments for diseases and disorders which previously had very limited therapeutic options available. Viral vectors are well recognised as valuable tools for introducing genetic material into mammalian cells to compensate for damaged or dysfunctional DNA.

One type of viral vector in particular – gammaretrovirus (also referred to as retrovirus) – has recently witnessed a surge in popularity amongst CGT developers due to the many advantages it offers, both in terms of efficacy and manufacturability.

Viral Vectors for CGT

The past two decades have seen treatment options for many challenging diseases expand with the advancement of CGTs. Although in the past these therapies predominantly targeted rare diseases, the capabilities of technologies like viral vectors have progressed to a point where we are seeing growing numbers in the development pipeline geared towards a wider variety of diseases. These range from metabolic conditions to respiratory diseases and cardiovascular diseases (1).

However, the most common therapeutic area targeted by gene therapies currently is cancer (1). Of the 19 approved gene therapies (including modified cell therapies), 12 of these target cancer indications (1). With cancer accounting for the death of approximately 1 in 6 people globally in 2020 alone, it is no surprise that drug developers are working hard to find new, alternative therapeutics to help patients (2).

Growing numbers of those in the biopharma industry are realising the potential of gene therapies for the treatment of cancer and other diseases, causing the global CGT market to expand rapidly. This is highlighted by the global CGT market being predicted to grow between 2021 and 2027 at a compound annual growth rate (CAGR) of 39.62%, to reach a value of $36.92 billion (3).

Retroviral Success in CAR T Cell Therapy

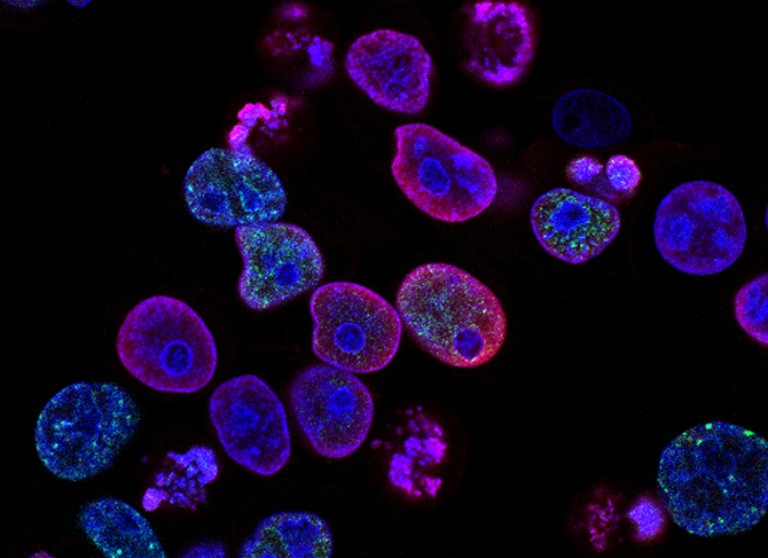

One of the key drivers for CGT market growth has been the success of chimeric antigen receptor (CAR) T cell therapies (2). Currently the most common technology in the genetically modified cell therapy pipeline, CAR T cell therapies specifically recognise cancer cells and elicit a targeted immune response causing cancer cell destruction. This is achieved by modifying patients’ extracted T cells to introduce CAR genes (typically using viral vectors), and reintroducing the cells to the patient. There are currently six CAR T therapies approved by the FDA, with the first (Kymriah) being approved in 2017, and others having been subsequently used to treat lymphomas, certain types of leukaemia, and multiple myeloma (4). Of these, the majority rely on viral vectors of the Retroviridae family (lentivirus and gammaretrovirus) to introduce the CAR genes.

Retroviral Vector: An Ideal Candidate for CGT Applications

The success of retroviral vectors (RVs) as a tool for introducing genetic material to patient cells can be attributed to a number of factors associated with the characteristics of the viral particles and the manufacturing methods required for their production. With all of these factors considered, it is no surprise that more and more developers are leaning towards the use of RVs for their CGTs.

Gammaretrovirus Properties and Characteristics

Retroviral vectors offer a variety of physical properties and characteristics that make them particularly well-suited to the delivery of genetic material such as CAR genes. As spherical enveloped virions with a diameter of 80-100nm, retroviral vectors have a large cassette capacity (up to 8.5kb) compared with adeno-associated viral cassettes (up to 4.5kb). For the treatment of many diseases, the genes that must be introduced to target cells are large, meaning that delivery can only be achieved using vectors like retrovirus that offer sizable cassette capacities. Like lentiviruses, retroviruses are also able to integrate transgenes into the host cell genome. This enables the long-term, stable expression of the gene introduced, which is also passed down to progeny cells.

Advancements Facilitating Safer Applications

There have been concerns in the past surrounding the safety of retroviral vectors for CGTs stemming from their propensity to integrate the transgene into the host genome near oncogene promoters. Consequently, their use had been associated with the potential development of cancer (5-7). Despite this possible safety issue, there are still many gene therapy applications that do not involve the modification of patient cells that produce progeny, and therefore do not have the same level of associated risk. Compared with cells like hematopoietic stem cells, mature T cells have been shown to be less prone to oncogene transformation to produce a malignant phenotype following retroviral transduction (8). As a result, the use of retroviral vectors for CAR T cell therapies (where mature T cells are modified) has expanded rapidly.

Recently, CAR natural killer (NK) therapies have come into focus as an alternative therapeutic option to CAR T cell therapies. As lymphocytes with a unique mechanism enabling pathologic cells to be distinguished from normal tissue, NK cells are able to rapidly identify and destroy abnormal, virally infected, and tumour cells (9). Using retroviral or lentiviral vectors (LV), CAR genes can be introduced into these cells to produce a therapy offering improved efficacy and increased control of adverse effects such as cytokine release syndrome (CRS) compared with CAR T therapies (9). These advantages have appealed to gene therapy developers and, as of June 2020, there were 19 clinical studies using CAR NK cells underway (10).

Additionally, advances in genetic engineering have enabled the safer utilisation of retroviral vectors for CGT applications. Similar safety principles and genetic modifications to those used in the lentiviral field have helped to reduce the likelihood of cancer development when using retroviral vectors. For example, self-inactivating (SIN) modifications to RVs can prevent enhancer and promoter sequences in long terminal repeats (LTRs) from activating adjacent cellular oncogenes after transgene integration.

Image: DCStudio on Freepik

Improved Scalability With Stable Producer Cell Lines

When considering the manufacturability of viral vectors, one of the most common issues surrounds the scalability of upstream processes. As opposed to relying on transient transfection for the production of every batch, necessitating the use of often expensive clinical-grade plasmids and transfection reagents and introducing possibilities for variability, retroviral manufacturers can develop stable producer cell lines. Generation of stable producer cell lines – where genes for viral vector production are integrated into the producer cell genome – will generally follow the same recommended method. This will involve transfecting the producer cell with a packaging plasmid (encoding gag and pol) and an envelope plasmid (encoding env), and the genes integrated. The genes encoded on the envelope plasmid will infer the ability to express different envelope proteins, providing an opportunity for viral vector pseudotyping. Following packaging and envelope plasmid transfection, a transfer plasmid with the transgene of interest will then be introduced. The stable integration of the genes needed for retrovirus generation means that transfected clones can be serially diluted to isolate single clones, allowing for the selection of a high-titre clone for stable master cell bank (MCB) production. The ability to produce stable cell lines is a key reason why developers often favour retrovirus, as producing equivalent cell lines for other viral vectors, such as lentivirus, can be a significant challenge due to envelope protein toxicity.

Additionally, compared with transient transfection, stable producer cell lines offer a number of key benefits:

• Decreases clinical-grade transfection reagent and plasmid costs

• Simplifies upstream culture and harvest

• Reduces batch-to-batch variability

• Generates greater quality viral particles

Relatively Simple Downstream Processing

As well as offering advantages during upstream processing, retroviral vectors also have distinct benefits during downstream processing (DSP), often being relatively simple. This is partly because retroviruses are commonly used for ex vivo therapeutic applications, rather than in vivo. The strategy for DSP in retroviral production will largely depend on the characteristics of the viral particles, particularly the envelope proteins that are encoded on the envelope plasmid. Generally, retroviruses will be harvested in the supernatant with the first step being membrane filtration. Additional steps could include tangential flow filtration (TFF) and anion exchange chromatography (AEX). Although retroviral purification could only require very few steps, developers must remember that these viral vectors are typically temperature-sensitive, and their stability must be maintained throughout this process.

Retroviral stability must also be considered throughout processes aiming to ensure sterility. As the typical final step of the downstream process, purified and concentrated viral vectors will be passed through a sterile grade filter. However, the large size of gammaretroviral particles means that this process is often associated with a significant loss in viral titre. To minimise this loss, RV developers should consider the advantages of qualified aseptic processing, which often alleviates the requirement for a sterile filtration step.

Availability of Single-Use Technologies

The manufacturability of retroviruses has been further enhanced by the availability of equipment that eases scalability.

Producer cells used for the production of retroviruses can either be adherent or suspension cultures. Adherent cultures offer high production titres and are ideal for development stages, however, traditional 2D systems used for their growth mean that scaling is a challenge. The need for more and more 2D culture vessels to meet the expanding incubator space for the scaling volumes can be challenging when floor space is limited. Fixed-bed bioreactors with a 3D matrix with highly porous microfibre surfaces are an ideal alternative, facilitating scalability with single-use properties, which help to minimise the risk of contamination.

Furthering the possibilities for scaling, developers could also take time to adapt cell lines to be grown in conventional stirred-tank bioreactors and rocking bags, both offering single-use capabilities for minimal contamination risk and faster turn-around between batches or projects. Although adapting cell lines can be an arduous task, this could prove beneficial in the long run, particularly when reaching commercial scales for certain indications.

Looking Forward

When examining the advantages that retroviral vectors can offer as a tool for CGTs, it is no wonder why it is quickly becoming a preferred choice of viral vector for ex vivo applications. With CAR T therapies now accounting for 49% of genetically modified cell therapies in the development pipeline, the need for retroviral development and manufacturing can only be expected to increase (1). However, reaching the point where retroviruses offer safety, scalability, and relatively simple purification processes has relied on viral vector expertise and experience, with careful genetic modification and the development of intricate processes. CGT developers will need to carefully consider relying on those with experience in the retroviral space to ensure that they realise the advantages these viral vectors can offer.

References

- American Society of Gene + Cell Therapy. Gene, Cell & RNA Therapy Landscape Q1 2022 Quarterly Data Report

- Visit: who.int/news-room/fact-sheets/detail/cancer

- Visit: businesswire.com/news/home/20220201006057/ en/36.92-Billion-Cell-Gene-Therapy-Market---Global-Outlook-Forecasts-2022-2027---ResearchAndMarkets.com

- Visit: cancer.gov/about-cancer/treatment/research/car-t-cells#:~:text=Since%202017%2C%20six%20CAR%20T,%2C%20most%20recently%2C%20multiple%20myeloma

- Hacein-Bey-Abina S et al, LMO2-associated clonal T cell proliferation in two patients after gene therapy for SCID-X1, Science, 302(5644): pp415-9, 2003, doi: 10.1126/science.1088547.

- Howe SJ et al, Insertional mutagenesis combined with acquired somatic mutations causes leukemogenesis following gene therapy of SCID-X1 patients, J Clin Invest, 118(9): pp3143-3150, 2008

- Braun CJ et al, Gene therapy for Wiskott-Aldrich syndrome--long-term efficacy and genotoxicity, Sci Transl Med, 6(227): pp227ra33, 2014

- Newrzela S et al, Resistance of mature T cells to oncogene transformation, Blood 112(6): pp2278-2286, 2008

- Fang F et al, Challenges of NK cell-based immunotherapy in the new era, J Front Med, 12(4): pp440–50, 2018

- Xie G et al, CAR-NK cells: A promising cellular immunotherapy for cancer, EBioMedicine 59:102975, 2020, doi:10.1016/j.ebiom.2020.102975

As CSO, Pratima Cherukuri brings over 15 years of experience in viral vector production to Genezen, holding previous positions at Covance Laboratories and Indiana University Vector Production Facility. She is responsible for leading the development of scalable, robust, and economically viable upstream and down processes, as well as the qualification of analytical assays for product release and characterisation of viral vectors and transduced cells.