Manufacturing: Tablets or Capsules?

Multi-particulate formulations: the power of many

After assessing the various routes of drug administration, oral delivery stands out as the safest and, as a result, the most universally accepted among patients. Single-unit dosage forms, including tablets followed by capsules, have been identified as the preferred designs for immediate or modified release formulations

Subhashis Chakraborty and Ananya Sen at ACG Capsules

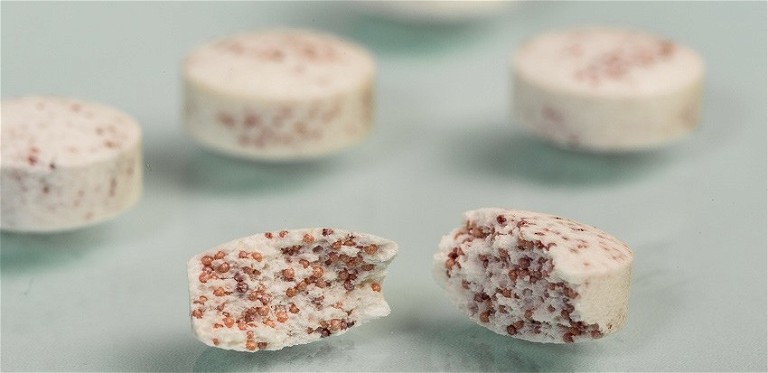

Traditionally, multi-particulates are filled into empty hard capsules using automated capsule filling machines. However, more recent technologies have enabled pellets to be compressed into multiple-unit pellet system (MUPS) tablets or pellet-containing tablets. Once these special tablets are exposed to the aqueous environment of the stomach, they disintegrate rapidly into individual pellets, releasing the drug like uncompressed pellets filled in capsules.

MUPS technology has gained considerable acceptance, particularly in the European market, with a number of products coming to the fore, including: Beloc ZOK (metoprolol succinate sr plus hydrochlorothiazide), Antra MUPS (omeprazole) and Prevacid SoluTab (lansoprazole), Nexium (esomeprazole), Galanil PR (galantamine HBr), Lipidown (orilistat), Esomezol (esomperazole sr), Toprol XL (metoprolol succinate) and Cartia (diltiazam).

Since the total drug is divided equally into many units in a multiple-unit system, it demonstrates several advantages over single-unit systems. When administered orally, these particles (less than 2mm in size) distribute evenly across the extensive surface area of the stomach. They behave like fluids and have a shorter retention time. Their small size also facilitates uniform gastric distribution, potentially reducing food-induced variations in inter- and intra-individual bioavailability, minimising chances of side effects and local toxicity. MUPS tablets can also greatly reduce the risk of premature dose dumping leading to drug degradation or gastric irritation due to any failure in functional coating. This is because a failure of a few units may not be as detrimental as the failure of a single-unit system. Moreover, MUPS tablets also offer the possibility of adjusting dosage strengths, administering incompatible drugs together and combining multi-particulates with different drug-release rates to customise the release profiles. However, despite the various advantages that this unique dosage form provides, the appropriate presentation of these multiple units in the final formulation must be carefully considered. Should these pellets be filled in capsules or compressed into tablets? The best way to determine this depends on a comprehensive understanding of the overall formulation and manufacturing process of the MUPS technology.

Key variables in MUPS tablet development

Unlike capsules, MUPS technology requires special excipients and critical process parameters to enable safe and easy compression. This ensures the pellets retain their properties and that their drug release profile is unaffected. Some of the essential variables determining the success of MUPS tablets include:

- Particle size of coated pellets

- Flexibility and thickness of functional coating

- Type and quantity of cushioning agent

- Tablet compression force.

In capsule filling, there are no size limitations for pellets. Usually, larger pellets are preferred as they are easy to manufacture and handle. However, for MUPS, a smaller particle size of pellets is preferred as they are easy to compress and present minimal risk of pellet damage. Special excipients, also referred to as cushioning agents, are used as extra granular material for compression. Since these excipients are available in the powder state, they are often granulated to improve the particle size and density that help to ensure a homogenous distribution of the pellets in the excipient blend. It also minimises the possibility of size separation on the turret during tablet compression, thus maintaining content uniformity in the tablets.

It is also important to realise that, by virtue of using smaller-dimension pellets, the resultant surface area increases exponentially as the particle size decreases. This demands higher polymer coating build up, which adds to the processing time and raw material cost. Moreover, the functional polymer coating must be flexible enough for the pellets to deform but not rupture under high compression force. This is typically addressed by using polymers that are inherently flexible or by adding the optimum amounts of plasticisers. Usually, a higher coating build-up is preferred in these formulations to compensate for any slight damage without compromising the release profile.

Finally, from a process perspective, the compression pressure is the most critical parameter. The mechanical properties of MUPS vary significantly from conventional tablets.

Therefore, the compaction force required for pellets and powdered excipients are also very different. And the process becomes more critical if the pellets are functionally coated to modify the drug release. This requires an extremely tightly controlled manufacturing process. For example, the range of compression force is kept narrow to ensure optimum pressure. Higher compression forces can damage the pellets, while low and inadequate compaction can result in friable tablets. The development of dedicated tablet compression machines with special turret designs and reduced vibration in recent years has helped to prevent blend segregation during operations.

“ From a patient perspective, capsules also cater to paediatric and geriatric patients with swallowing difficulties ”

Despite all precautions, there remains the potential for pellet damage and the drugs being exposed to the external environment. This can sometimes manifest as minute spots on the surface, which are especially noticeable in sensitive active pharmaceutical ingredients (APIs). However, in most cases, the therapeutic potency may not be significantly compromised. But, since such colour changes interfere with the aesthetics of the final formulation, an additional film coating becomes necessary to mask any possibilities of market rejections.

A prescription for the drug delivery dilemma

The entire MUPS development process is a complex one. The combined impact of the raw materials along with critical process variables makes it extremely labour-intensive, time-consuming and expensive. In the case of capsules, however, the absence of additional excipients, ready-made shells to fill and a simple capsule filling process ensure far less complexity.

Moreover, for scaling up or down pellet production for different strengths, capsules are much easier to handle. The absence of any extra granular powder excipients eliminates the possibility of dust generation, ensuring a safer and clean working environment. From a patient perspective, capsules also cater to paediatric and geriatric patients with swallowing difficulties by allowing the dispersion of multi-particulates directly into liquid or soft food, usually referred to as the ‘sprinkle’ application. Moreover, encapsulating pellets don't require any additional or specialised infrastructure, expertise or technology since it employs a standard capsule filling process.

Tablets are often favoured over capsules due to the lower production costs, but it is important to look at the bigger picture here. The total cost of ownership (TCO) for developing MUPS tablets extends beyond initial expense, requiring a high degree of precision that is achieved using not only specialised excipients and machinery but also expertise.

These often-overlooked factors and hidden costs necessitate the importance of a comprehensive TCO analysis in making informed decisions about choosing the right drug delivery system.

The questions we need to answer include: is it worth developing a product loaded with so many risk factors? Why do patients need to be exposed to unnecessary excipients with added costs? Why are simple available options no longer considered simple? Why are aesthetics more important than patients’ health? It is high time that we, the custodians of health, take cognisance and act accordingly for a better, healthier future.

Subhashis Chakraborty holds a PhD in Pharmaceutical Sciences. Presently, Dr Chakraborty holds the position of general manager, Global Product Management, for ACG Capsules. In this role, he is responsible for spearheading the new capsule technologies for pharmaceutical and nutraceutical applications, right from development to commercialisation. He has more than 15 years of experience with different MNCs in senior management roles, working across R&D, business development and product management.

Ananya Sen is a marketing communications specialist at ACG with a degree in Pharmacy and has over a decade of experience in the pharmaceutical industry. Her roles have spanned from pharmaceutical journalism and drug regulatory affairs to marketing. In her current position, she is responsible for overseeing brand communications across all ACG's group companies.