World-class drug product capabilities: from formulation to commercialisation

Comprehensive drug product services

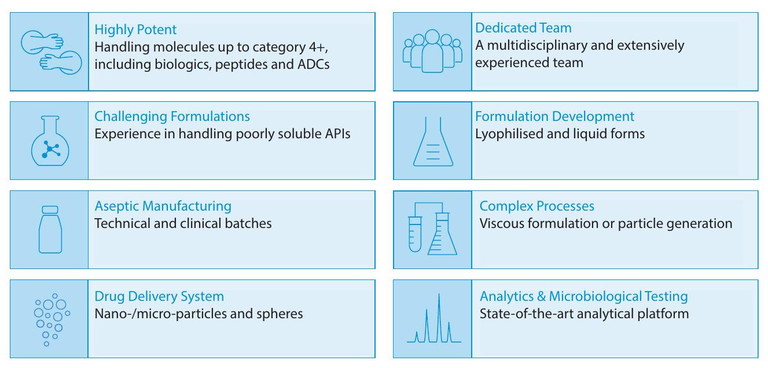

Our expertise in drug product development encompasses a wide range of pharmaceutical services. From formulation design to commercial-scale manufacturing, we specialise in efficiently bringing your drug product to market while ensuring full compliance with regulatory standards. Our highly skilled team at our state-of-the-art facility in Saint-Beauzire, France, ensures that your drug product is manufactured with precision and meets the highest quality standards.

At CARBOGEN AMCIS, we have the specialised skills and extensive experience required to develop and manufacture sterile drug products. Our expertise spans pharmaceutical sciences, microbiology, engineering and process development, enabling us to deliver exceptional results. We excel in drug formulation, sterilisation methods and aseptic pharmaceutical manufacturing. With a deep understanding of regulatory standards, we ensure the safe development and production of sterile drug products in full compliance with GMP and other applicable guidelines.

We offer drug product development services, industrial transfer, clinical and commercial drug product manufacturing, release testing and stability studies as well as qualified person (QP) services and regulatory support.

Key Facts

• Over 20 years of expertise as a drug product CDMO

• Specialising in the development and manufacturing of sterile drug products

• Providing both liquid and lyophilised drug product solutions

• State-of-the-art facility designed for clinical and commercial supply, compliant with Annex 1 regulations

• Expertise in handling complex compounds, challenging formulations and high-potency compounds.

Capabilities

• Clinical and small-scale commercial manufacturing

• Advanced formulation expertise for complex and high-potency compounds

• Aseptic filling under isolators with integrated lyophilisation technology

• Packaging options: vials (current) and pre-filled syringes and cartridges (future).

Why choose us?

• High-potency expertise: Handling of molecules up to Category 4+, including biologics and peptides

• State-of-the-art infrastructure: Two automated production lines optimised for flexibility and scalability

• Regulatory excellence: Fully compliant with Annex 1 guidelines.

Key features

Two fully automated production lines

• Line 1: Liquid and lyophilised drug products

• Line 2: Liquid formulations in vials, with future capabilities for pre-filled syringes.

Specialised environments

• Low-temperature and inert-atmosphere capabilities for complex formulations

• Advanced isolator technology ensuring maximum sterility.

Analytical excellence

• Dedicated microbiology and biochemistry labs

• Stability testing in compliance with ICH guidelines.

Sustainable science: innovation for a greener future

• Energy-efficient equipment and processes

• Waste reduction initiatives

• Commitment to green chemistry principles.

Watch our video on advancing ADC and drug product solutions